Introduction

Over the years, plumbing and drainage has evolved a lot. It has come a long way from the usage of clay pipes that were used to supply water and carry sewage in ancient times to a variety of materials used now. Today, we use different types of pipes for plumbing and drainage systems.

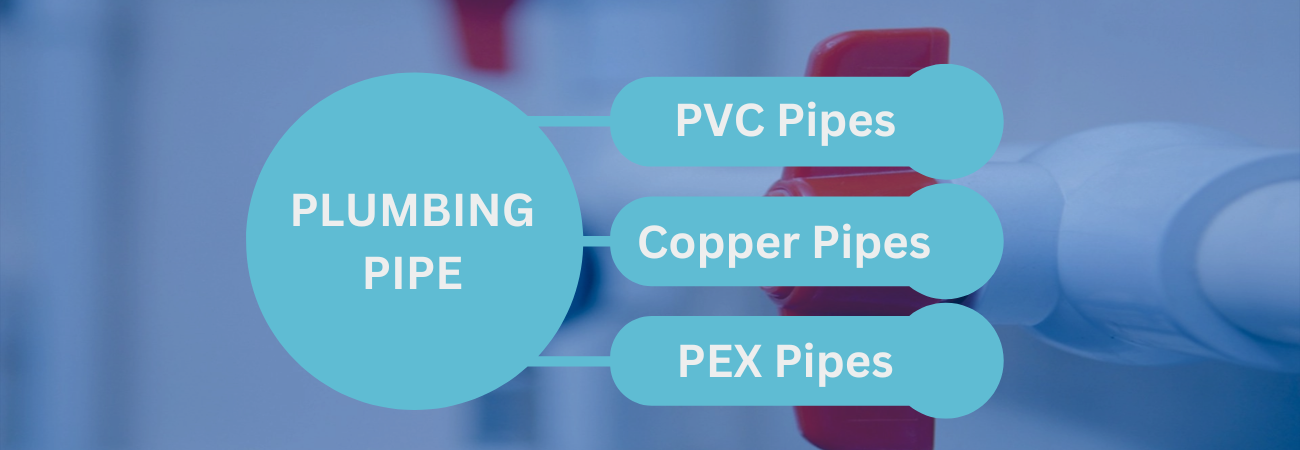

There are a major of seven types of water supply pipes that are commonly found in houses these days. They are PEX, PVC, ABS, Flexible Copper, Rigid Copper, Cast Iron, and Galvanized pipes. When it comes to changing the existing plumbing system in your old house or to install a plumbing system in your new house, you may find it confusing to choose among the types of pipes available in the market.

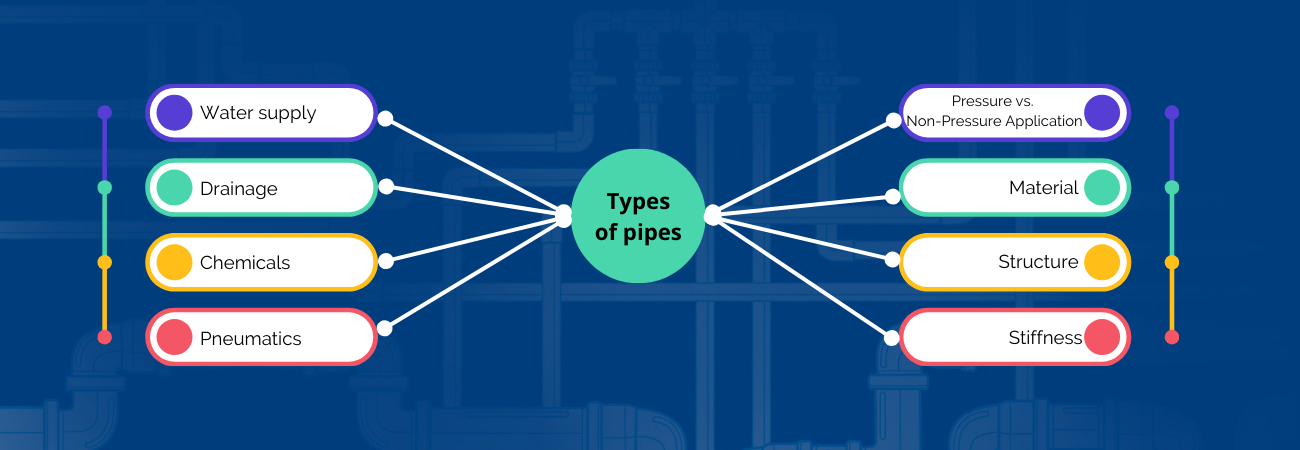

What Types of Pipes Are Used In Homes Based on Appl

ication

1. Water supply

Pipes are used in transporting drinking water. They are used in water distribution networks where the water is treated before distribution and chlorinated to prevent contamination. Types of water supply pipes are PEX, UPVC, CPVC, Rigid and flexible copper pipes, and Galvanized steel pipes.

- PEX or Polyethylene cross-linked pipes are widely used for water supply in residences and small business establishments.

- Unplasticized PVC (UPVC) is used for cold water supply while Chlorinated PVC (CPVC) pipes can withstand higher temperatures and are used to carry hot water.

- Rigid copper pipes are one of the common types of water supply pipes used for water supply within the home as they don’t come with any health risks.

- Flexible copper pipes are used in final runs to water refrigerators, water heaters, and sinks.

- Galvanized steel pipes are used for decades at home for water supply, gas supply, fire fighting installations, and other purposes. Galvanized steel pipes are extremely strong.

2. Drainage

Drainage pipes are those pipes that facilitate the transport of wastewater from one place to another. They are required in residential and commercial buildings to dispose of wastewater. Some of the pipes used in drainage systems are,

- Corrugated Polyethylene drainage pipes, PVC, concrete, clay, and cast-iron pipes.

- Polyethylene drainage pipes are strong, durable, and cost-effective solutions for an efficient drainage system. They are chemically inert plastic and are highly corrosive and abrasion-resistant

- PVC Drainage Pipe – The polyvinyl chloride pipes are the most common and widely used in drainage systems. These pipes are affordable, durable, and easy to install. They are used a lot in toilet drain lines.

- Concrete drainage pipes are cost-effective, strong, and durable. They are eco-friendly and are non-flammable, unlike plastic pipes.

- Clay drainage pipes are strong and eco-friendly. The only drawback is that they have to be replaced over some time as they are likely to develop cracks when exposed to extreme weather conditions and water pressure.

- Cast Iron pipes are used in home sewer applications. They are tough and durable. Cast Iron pipes are widely used by municipalities because of the low maintenance it requires and can last for more than a hundred years.

- Galvanized pipes have been used for drainage systems since the early 1900s. These pipes are cost-efficient and easily available. However these pipes were later replaced by plastic or PVC pipes due to high maintenance, discoloration, and leakage problems encountered.

3. Chemicals

Stainless steel pipes are widely used in the chemical industry. Stainless steel is a versatile material comprised of a steel alloy and a small percentage of chromium. Chromium is added to make the material resistant to corrosion. Apart from SS pipes, Polyvinyl Chloride (PVC) or Unplasticized Polyvinyl Chloride (UPVC) pipes can also be used in the chemical industry based on the chemical resistance chart provided by the manufacturer.

4. Pneumatics

Plastic and metal pipes are used in compressed air systems. Pipes and fittings are the components that connect everything in a compressed air system.

- Ideal plastic pipes for compressed air are made of Acrylonitrile Butadiene Styrene (ABS), Polyethylene (PE) piping, and High-density polyethylene (HDPE) piping.

- Metal pipes like black steel pipe, galvanized steel pipe, copper pipe, aluminum pipe, and stainless steel pipe are used in air compression systems.

5. Pressure vs. Non-Pressure Application

Pressure Applications

ABS, PE, PVC, cast iron, steel, cement concrete, asbestos cement pipes are used in pressure piping. They are used in a wide range of applications including water supply, sewerage, gas reticulation, compressed air, mine and slurry pipelines, coal seam gas collection, irrigation, and drainage.

Non-pressure applications

Polyvinyl Chloride (PVC), Polypropylene (PP), and PE pipes are used for non-pressure applications like storm water drainage pipelines, ocean outfalls, road culverts, gravity sewer mains, ventilation ducts, etc.

6. Material

Metal pipes

Metal pipes include Cast-iron pipes, Galvanized Iron pipes, Copper, Aluminum, and Stainless Steel (SS) pipes.

Non-metal pipes

Non-metal pipes include cement and ceramic pipes.

Asbestos Cement pipes are made of asbestos paste and cement compressed by steel rollers to form a laminated material. This material is of great strength and density.

Plastic Water Pipes:

Some of the plastic pipes available in the market are

PVC – Polyvinyl Chloride Pipes, HDPE- High-density polyethylene (HDPE) piping. LLDPE – Linear low-density polyethylene (LLDPE), MDPE – Medium-density polyethylene, CPVC- Chlorinated Polyvinyl Chloride, PP- Polypropylene,

PPR – Polypropylene Random pipes, PEX – Polyethylene cross-linked pipe, PERT – Polyethylene of Raised Temperature, PVDF – Polyvinylidene Fluoride, ABS – Acrylonitrile Butadiene Styrene, PU – Polyurethane Pipe, FPVC – Fusible PVC pipes and Rubber pipes.

7. Structure

Solid Wall

Solid wall pipes are those extruded pipes consisting of one layer of a homogeneous matrix of thermoplastic material ready for use in a pipeline.

Structured wall

Structured wall pipes are designed to develop maximum pipe stiffness and other physical, mechanical, and performance requirements.

Multi-layer

The multi-layer pipes are composed of four layers. The first layer is made of PEX and this layer gets in contact with the liquid to be transported. The second layer is an aluminum layer, the third layer is the external protective PE (Polyethylene) layer. Between each layer, the pipe has two intermediate adhesive layers to keep them joined.

8. Stiffness

Flexible Pipes:

Flexible pipes are the type of water supply pipes used to connect the plumbing fixtures and appliances. The flexible pipes are not directly connected to the water supply pipe but are connected to a fixture shutoff valve attached to the water supply pipe. Braided nylon flex tubes, stainless steel braided flex tubes, PVC flex tubes, and polymer-coated flex tubes.

Rigid Pipes

Rigid pipes are made of plain concrete, reinforced concrete, vitrified clay, cast iron, and asbestos cement. They have the strength to support more load.

TYPES OF PIPE JOINTING SYSTEMS

THREADED JOINT

It is the mechanical joint between threaded pipes or between a threaded pipe and threaded fitting.

SOLDERING

It is a joining process used to join together different types of metals by melting solder.

METAL HEAT WELDING

It is a fabrication process that joins metals or thermoplastics by using high heat to melt the parts together.

PLASTIC HEAT WELDING

It is the process of creating a molecular bond between two thermoplastics.

SOLVENT CEMENT

It is either available in the liquid or gel forms. They are used to join PVC pipes and other types of plastics. Solvent cement is very convenient to use.

RUBBER RING

In this technique, a fluid seal is provided by compressing a rubber ring housed in the socket of a pipe or fitting when the spigot is passed into the socket.

CRIMPING

Crimping is a device used to join two pieces of metal. Either or both the metals are deformed in this process to hold each other.

SNAP-FIT

It is an assembly method used to attach flexible parts, especially plastics to form the final product. The interlocking components of the parts are pushed together.

COMPRESSION

This technique is used to connect two pipes or a pipe and a fixture or valve.

For any queries, contact the plumbing experts at Ajay pipes on the Toll Free No. : 1800-11-4050 or via email at our email address info@ajaypipes.com