Introduction

PVC PIPE JOINTS:

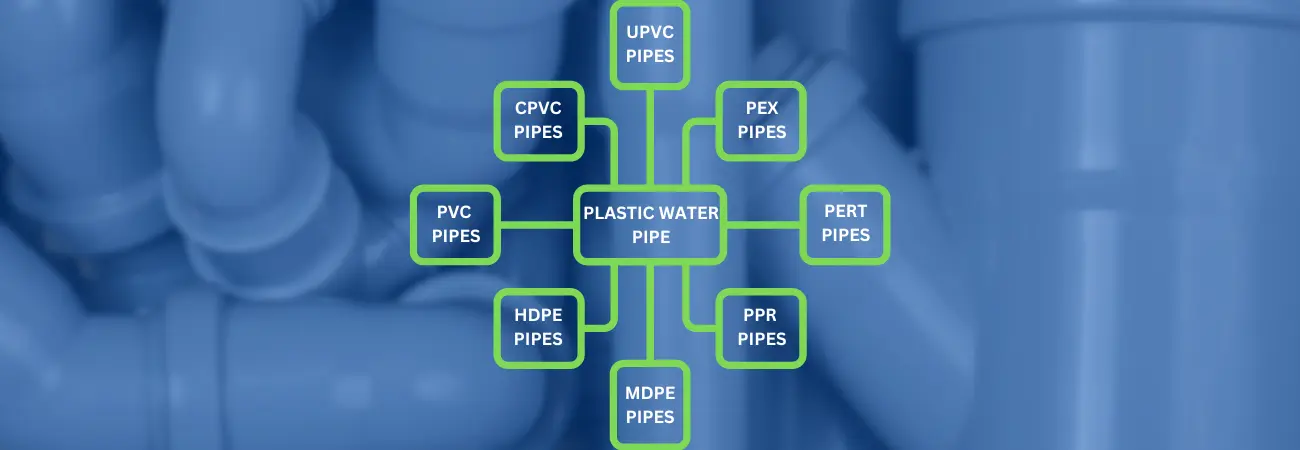

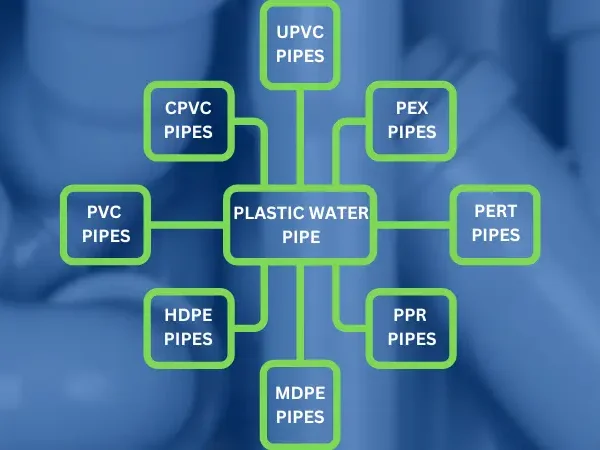

PVC stands for Polyvinyl Chloride. It is a man-made plastic mainly used to transport water and is widely used in drainage and water distribution systems. Pipe joints are crucial in any piping system as they decide the life of the system. PVC Pipe joints serve many purposes such as

a. Lengthen the pipe

b. Change the direction of pipeline

c. Take out multiple outlets

d. Connect the pipe to different elements such as pumps, sprinklers, faucets, showers and other accessories.

PVC pipes and PVC Pipe joints are made to last long, generally having a life-span of about 30-50 years provided the joints are properly sealed and good quality solvent cement is used. PVC pipe joints must be able to withstand the pressure of each pipe.

Importance

Pipe joint play a major role in varying industries that ensure efficient transportation of gasses and fluids. Understanding varying types of joints and its applications is crucial for various professionals working in construction, plumbing, and engineering. These are joints that efficiently connect the pipes together, that allows efficient flow of gasses and liquids.

Moreover, the joints offer structural integrity that prevents leakage and ensures proper transfer of fluids. Proper installation of the joints has the ability to withstand high pressure and temperature, along with other environmental factors. All these features make the joint more crucial, maintaining its safety and reliability of the pipes.

Leakage free tips

- Ensure to measure and cut the pipes properly to ensure its proper fitting, as a better fitted joint doesn’t leak.

- Clean the fitting and pipe surfaces frequently before applying tape or any adhesive, as the dirt could compromise pipe’s integrity.

- Make sure to abide by the manufacturer’s guidelines for using adhesive, as varying products might depict varying applications.

- Allow enough time to cure the solvent cement to set before system pressurizing, as this would ensure a strong bond and lowers leakage risk.

Different pipe joint types are as follows :

Welded joint – Two types of welded joints are there for pipe joining. One being butt welded joint where two pipes of same diameter are placed end to end and welded, while the other being socket welded where two pipes of different diameters are welded together using suitable fittings.

Threaded joint – Threaded joints have internal threading in one pipe and external in the other, both can be screwed to fit and form a leak proof joint. Both metal and PVC plastic pipes have threaded joints.

Brazed joint- Brazing is the joining of two pipes using a molten material as filler at very high temperature. Brazing is done in metal pipes, especially copper pipes and the filler is mostly tin.

Soldered joint – Soldering joints are similar to brazed joints but the joining is at slightly lower temperature than in the brazed joints. Soldering is used to join copper and copper alloy pipes.

Grooved joint– Grooved couplings are used to seal the joint between two pipes. These grooved couplings are made of iron.

Compression joint- Pipes having plain ends are joined using appropriate size fittings in compression joints. Mostly, threaded fittings are attached to screw the pipes together.

Flanged joint- when flange components are used to join two pipes, it is called a flanges joint. These joints are suitable for high pressure wide pipes.

Solvent cemented joint: These require special chemicals known as solvent cements which makes a strong joint. The process involves melting the pipe and fitting layer and fusing it together while filling up any air gaps with the cement.

Rubber ring joint: This type of jointing is fast and easy requiring the lowest amount of skill. Special rubber ring inside the socket forms a seal once the spigot side of the pipe or the fitting is inserted inside the socket.

PVC Pipe Connector

PVC pipes require PVC pipe connectors to join them together. These are sometimes also known as PVC fittings or PVC pipe joints or PVC pipe accessories. PVC Pipes normally use either solvent cement type connectors or rubber ring type connectors. These fittings are available in a wide range varying in sizes and types. The different PVC pipe connector types are:

- Tee

- Cross Tee

- Bend

- Wye

- Socket

- Reducer

- Cap

- Trap

- Plug

- MTA

- FTA

- Saddle

Ajay Pipes has earned the most number of certifications from top Indian and international firms.

Why Ajay Pipes :

Ajay pipes is a more than 50 years old manufacturer of PVC pipes and PVC pipe accessories, serving their customers with the best quality products and services.

- Latest technology and machinery for state-of-the-art products

- Use of virgin raw materials of utmost quality

- Strict quality standards

- 11 warehouses and dealers spread all across the country, Ajay Pipes is a pan-India seller of PVC drainline products.

- Plumbing experts and technicians are provided with training to enhance their skills.

For any queries, contact the plumbing experts at Ajay pipes on the Toll Free No. : 1800-11-4050 or via email at our email address info@ajaypipes.com