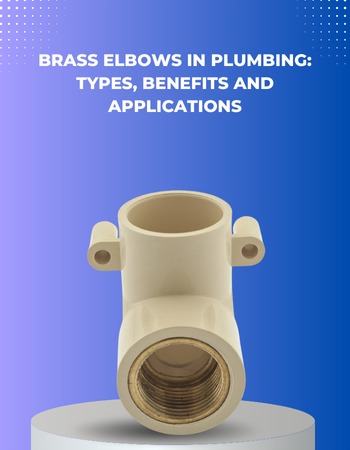

Brass Elbows in Plumbing: Types, Benefits and Applications

Introduction

A brass elbow is a plumbing fitting used to change the direction of water flow in pipelines, usually at a 90° or 45° angle. Made from high-quality brass, these elbows are widely used in CPVC, UPVC, and other piping systems due to their durability, corrosion resistance, and leak-proof performance.

In simple terms, a brass elbow fitting acts as a connector that allows plumbers to turn pipes without cutting or bending them, making installations more efficient and long-lasting.

Why Choose Brass Pipe Fitting Elbow in Plumbing?

Brass is one of the most trusted materials in plumbing because it offers the perfect balance of strength, longevity, and affordability. When used in elbows, it provides:

- Durability: Brass Pipe Fitting Elbow resist cracking and wear, even in high-pressure systems.

- Corrosion Resistance: Unlike steel, brass remains rust-free, ensuring durability in hot as well as cold water applications.

- Leak-Proof Joints: The precision threading ensures tight, secure connections.

- Versatility: Works with CPVC, UPVC, PPR, and other modern piping systems.

- Heat Resistance: Suitable for hot water lines and industrial uses.

Types of Brass Elbow Fittings

Brass elbows come in different variations to suit various piping needs. The most popular types include:

- CPVC Brass Elbow

A CPVC Brass Elbow combines CPVC plastic with brass threading for superior durability. It is widely used in hot and cold water plumbing because CPVC can handle high temperatures while brass ensures leak-free joints.

- Ideal for residential and commercial plumbing

- Prevents stress cracking common in plastic-only fittings

- Available in standard sizes such as ½ inch, ¾ inch, and 1-inch elbow brass.

- UPVC Brass Elbow

A UPVC Brass Elbow is designed for cold water distribution systems. UPVC provides chemical resistance while brass adds strength at threaded ends.

- Best suited for irrigation and cold-water supply

- Lightweight and cost-effective

- Long service life with minimal maintenance

- Brass Elbow 1 Inch

The brass elbow 1 inch is one of the most commonly used sizes in plumbing projects. It is preferred for water distribution lines, ensuring steady flow without leaks.

- Standard size for both CPVC and UPVC systems

- Suitable for residential and commercial projects

- Available in 90° and 45° angles

- Brass Elbow CPVC (Threaded)

The brass elbow CPVC type specifically caters to CPVC pipe installations with brass-threaded ends. This ensures:

- Higher durability than plain CPVC elbows

- Easy installation with Teflon tape or sealant

- Secure fit for high-pressure lines

- Elbow Brass (General Use)

The term elbow brass generally refers to standard brass elbows without CPVC or UPVC integration. These are typically used in metal piping systems and are popular in industrial settings.

Applications of Brass Pipe Elbow

Brass pipe elbow are versatile and widely used across industries. Their applications include:

- Residential Plumbing: Water supply in kitchens, bathrooms, and overhead tanks

- Commercial Buildings: Hotels, hospitals, and office complexes for reliable water distribution

- Industrial Systems: Cooling lines, compressed air lines, and chemical processing

- Agricultural Irrigation: Durable fittings for sprinkler and drip irrigation systems

- HVAC Systems: For heat and cooling fluid lines

How to Select the Right Brass Pipe Elbow?

When choosing a Brass pipe elbow for your project, keep these points in mind:

- Size Compatibility: Match the size with your pipeline (½ inch, ¾ inch, or 1-inch Brass pipe elbow).

- Pipe Type: Use a CPVC Brass pipe elbow for hot water applications, while a UPVC Brass pipe elbow works best for cold-water lines.

- Angle Required: Decide between 90° or 45° based on pipe layout.

- Threading Quality: Ensure precision threading for leak-proof connections.

- Brand & Certification: Always pick ISI-certified or reputed brands for safety and durability.

Elbow Brass Installation Guide

Installing a elbow brass is straightforward if you follow the right steps:

- Measure & Cut Pipe: Use a pipe cutter for clean edges.

- Deburr & Clean: Remove burrs to avoid leaks.

- Apply Sealant/Teflon Tape: Wrap threading to prevent leakage.

- Fix the Elbow: Hand-tighten first, then use a wrench carefully.

- Test for Leaks: Run water through the line and check joints.

Maintenance Tips for Elbow Brass

A elbow brass may last decades, but proper care ensures maximum efficiency. Here are some practical maintenance tips:

- Regular Inspection: Check for leaks, rust stains, or signs of thread wear.

- Avoid Over-Tightening: Excessive torque during installation can crack threads.

- Use Proper Sealants: Always apply Teflon tape or approved thread sealant to prevent leaks.

- Clean Water Supply: Hard water can cause scaling; using filters reduces deposits inside elbows.

- Timely Replacement: If you notice reduced water pressure or leakage, replace the elbow immediately.

FAQ:-

A brass elbow is used to change the direction of water flow in pipelines, usually at a 90° or 45° angle, without bending or damaging the pipe.

Brass elbows are stronger, more durable, and resistant to corrosion. They can also handle high water pressure and temperature, making them more reliable than plastic fittings.

Yes, CPVC types are best for hot and cold water lines, while UPVC types are ideal for cold-water distribution and irrigation.

Standard sizes include ½ inch, ¾ inch, and 1 inch, with both 90° and 45° angle options.

Yes, brass-based CPVC fittings are designed to withstand high temperatures, making them perfect for hot water applications.

Apply Teflon tape or thread sealant, hand-tighten first, and then use a wrench carefully to avoid over-tightening.

They are widely used in residential plumbing, commercial water supply, HVAC systems, industrial pipelines, and agriculture.

For any queries, contact the plumbing experts at Ajay pipes on the Toll Free No. : 1800-11-4050 or via email at our email address info@ajaypipes.com