PVC End Cap Guide: Secure & Seal Your Pipes with Confidence

Introduction

A PVC end cap is a simple yet crucial fitting used in piping systems to close the end of a pipe securely. Whether you’re working on a plumbing setup, irrigation network, or industrial system, end caps ensure that the pipeline is sealed off to prevent leaks, contamination, or unwanted flow.

These caps are typically made from Polyvinyl Chloride (PVC), a lightweight yet durable thermoplastic known for its chemical resistance and affordability. Whether you’re using PVC solvent cement or PVC solution to fit them, their installation is quick and reliable.

Why Use a PVC End Cap?

PVC end caps are essential in various plumbing and fluid distribution systems for the following reasons:

- Leak Prevention: Creates a watertight seal at the end of a pipe.

- Protects the system by blocking dirt, debris, and insects from entering the pipe.

- Temporary Sealing: Ideal for future pipe extensions or maintenance closures.

- Choose high-quality PVC-U material for durability and resistance to temperature changes.

Types of PVC End Caps

PVC end caps are available in several styles depending on their application:

1. Socket End Cap

- Fits over the outside of the pipe.

- Commonly used in residential plumbing.

2. Threaded End Cap

- Screws onto the threads of a pipe.

- Ideal for temporary sealing and easy disassembly.

3. Domed Cap

- Slightly bulged at the end for high-pressure applications.

- Offers added strength.

How to Install a PVC End Cap (Step-by-Step)

Installing a PVC end cap is a straightforward process if done properly. Here’s how to do it:

Tools & Materials Needed:

- PVC end cap

- PVC pipe

- PVC solvent cement

- PVC solution (cleaner/primer)

- Rag or cloth

Installation Steps:

- Clean the Pipe and Cap:

- Use a PVC solution to clean both surfaces.

- Remove any dust, grease, or moisture.

- Apply Primer :

- For a stronger bond, use a primer before applying cement.

- For a stronger bond, use a primer before applying cement.

- Apply PVC Solvent Cement:

- Spread cement on the outside of the pipe and the inside of the cap.

- Spread cement on the outside of the pipe and the inside of the cap.

- Connect the Cap:

- Push the cap onto the pipe with a twist for even distribution.

- Hold for 30 seconds until set.

- Allow to Cure:

- Wait 15–30 minutes before handling.

- Full cure may take up to 24 hours depending on cement type.

Common Applications of PVC End Caps

PVC end caps are widely used across different industries:

- Residential Plumbing: Sealing water lines or pipe ends in bathrooms and kitchens.

- Agricultural Irrigation: Temporarily capping off unused irrigation lines.

- Construction Projects: Testing pressure in pipe systems before final connections.

- Industrial Systems: Isolating sections for maintenance.

Related PVC Fittings to Consider

While working with PVC pipes, here are other essential fittings that enhance system efficiency:

- Built to endure internal pressure in hot and cold water systems.

- PVC Tee: Joins three pipes together at right angles for branching.

- PVC Coupler: Joins two pipes in a straight line.

How to Choose the Right PVC End Cap

When selecting an end cap, consider the following:

1. Pipe Size Compatibility

- Always match the end cap size to your pipe’s outer diameter.

2. Pressure Rating

- Check the cap’s pressure resistance if used in pressurized systems.

3. Application Type

- For permanent closure, go for solvent-weld caps.

- For temporary use, threaded caps work best.

4. Material Grade

- Opt for premium PVC-U material to ensure strength and withstand temperature variations.

Maintenance Tips for PVC End Caps

PVC fittings require minimal maintenance, but here’s how to ensure longevity:

- Inspect periodically for cracks or leaks.

- Avoid exposure to direct sunlight for long periods.

- Use compatible PVC solvent cement to prevent joint failures.

- During disassembly, avoid hammering or forcing the cap off—use proper tools.

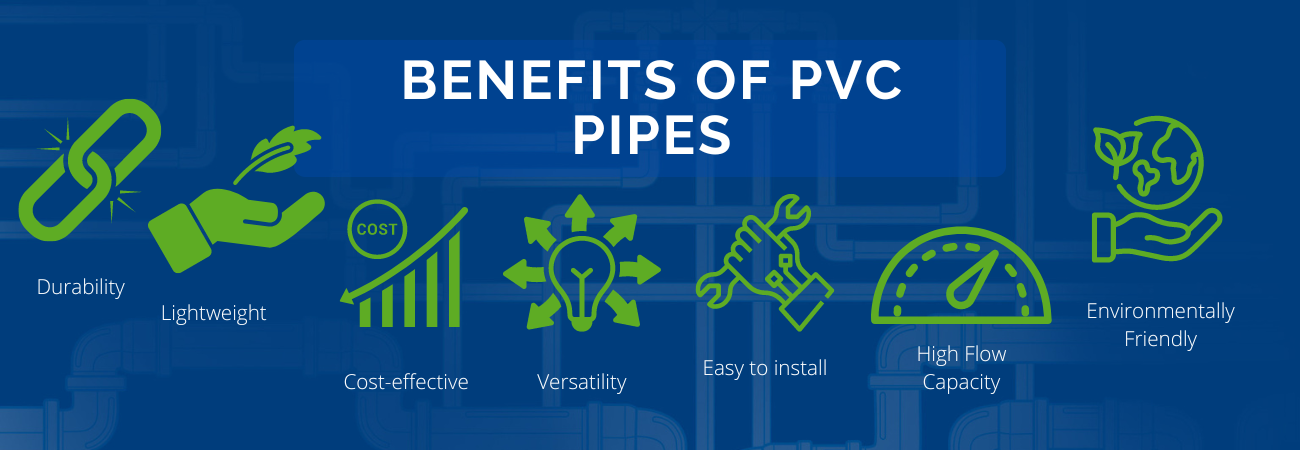

Advantages of Using PVC End Caps

Here are some standout benefits:

- Easy to install

- Cost-effective

- Corrosion-resistant

- Lightweight and durable

- Compatible with various other fittings

Commercial & Industrial Use Cases

For Builders & Contractors:

- Use in testing pipelines before commissioning.

- Seal lines temporarily during phased construction.

For DIY Enthusiasts:

- Ideal for home plumbing projects and temporary closures.

- Easy to store and reuse.

For Plumbers:

- An essential part of emergency plumbing kits.

Conclusion

A PVC end cap is more than just a pipe cover—it’s a critical component in ensuring leak-proof, reliable pipe systems. Whether you’re sealing a residential line or prepping a commercial plumbing system, using the right tools like PVC solvent cement and PVC solution ensures a strong, long-lasting connection.

By understanding the types, applications, and installation tips, you can confidently choose the best PVC end cap for your project.

FAQ:-

Yes, threaded PVC end caps can be reused as long as they remain in good condition. However, solvent-welded caps are intended for permanent use and cannot be removed without damaging the pipe.

A PVC cap is designed to cover the external end of a pipe, whereas a PVC plug is inserted into the pipe to seal it from the inside. Both serve to block flow but differ in how they are installed.

For socket-type PVC end caps, using PVC solvent cement is essential to create a secure, leak-proof bond. If the end cap is threaded, Teflon tape can be used instead to ensure a tight seal.

You can find reliable and long-lasting PVC end caps, along with other components like PVC valves and connectors, from reputable brands such as Ajay Pipes. They offer a wide variety of plumbing solutions, including durable fittings and solvent adhesives.

For any queries, contact the plumbing experts at Ajay pipes on the Toll Free No. : 1800-11-4050 or via email at our email address info@ajaypipes.com