Introduction

The Importance of a Professional Pipe Manufacturing Company

A professional pipe manufacturing company focuses on delivering consistent quality and long-term reliability. Pipes must handle pressure, temperature changes, and continuous water flow without cracking, leaking, or corroding. Poor-quality pipes can cause serious damage, increase maintenance costs, and even pose health risks.

Top manufacturers invest in modern production plants, trained engineers, and quality control laboratories to ensure that every pipe meets industry standards. Their goal is to provide piping systems that remain strong and efficient for decades.

Role of PVC and CPVC in Today’s Piping Systems

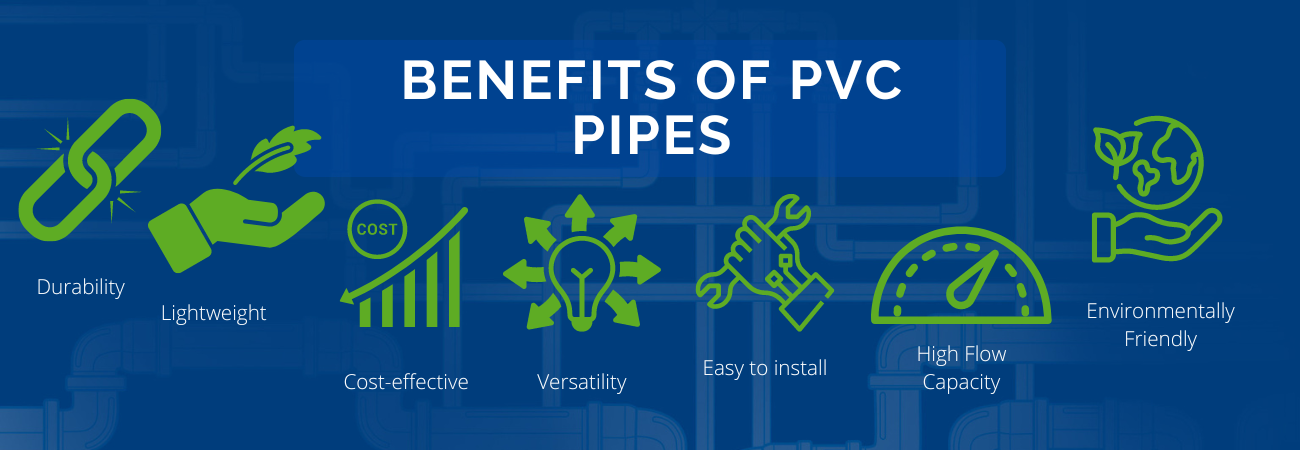

The evolution of piping materials has transformed how water and waste are managed. A well-established PVC pipe manufacturer produces pipes that are lightweight, rust-free, and cost-effective. PVC pipes are widely used in drainage systems, irrigation lines, and cold-water supply because they are easy to install and require minimal maintenance.

On the other hand, a reliable CPVC pipe manufacturer specializes in pipes that can handle high temperatures and pressure. CPVC pipes are commonly used in hot and cold water plumbing in homes, hotels, hospitals, and commercial buildings. Their heat resistance and durability make them ideal for modern plumbing systems.

Together, PVC and CPVC pipes provide flexible and efficient solutions for almost every type of project.

Why Water Supply Pipes Are So Important

Water supply pipes are responsible for delivering clean, safe water to homes and businesses. If these pipes are poorly made, they can leak, contaminate water, and lead to costly repairs. That is why it is essential to use pipes manufactured by a trusted pipe manufacturing company.

High-quality water supply pipes are designed to resist corrosion, maintain water purity, and withstand high pressure. They ensure that water flows smoothly and safely through the system, protecting both property and public health.

How Pipes Are Manufactured

The process of making pipes is highly technical and requires precision at every stage. First, raw materials such as PVC or CPVC resin are carefully selected for purity and strength. These materials are melted and shaped using advanced extrusion machines that form pipes of exact size and thickness.

After shaping, the pipes are cooled, cut, and inspected. They are then tested for pressure, durability, and resistance to impact and heat. Only pipes that pass these strict tests are approved for sale. A professional pipe manufacturing company follows these steps to ensure consistent quality and customer satisfaction.

Benefits of Choosing a Trusted Manufacturer

Selecting pipes from a reputed manufacturer offers several long-term advantages:

Superior Strength

High-quality pipes are built to handle pressure, temperature changes, and heavy usage without failure.

Health and Safety

Certified pipes prevent contamination and ensure that drinking water remains safe.

Cost Savings

Durable pipes reduce the need for frequent repairs and replacements.

Wide Range of Options

Leading manufacturers offer PVC, CPVC, and other specialized pipes for different applications.

Where These Pipes Are Used

Modern pipes are essential across many sectors, including:

- Homes and apartments

- Commercial complexes

- Hospitals and hotels

- Agricultural irrigation

- Industrial plants

- Municipal water supply and drainage

No matter the scale of the project, pipes form the foundation of efficient water and waste management.

How to Select the Right Pipe Manufacturing Company

When choosing a manufacturer, it is important to look beyond price. Check for product certifications, manufacturing standards, and customer feedback. A company that uses advanced technology, maintains strict quality control, and provides reliable customer support is more likely to deliver long-lasting products.

A strong reputation in the market is also a good indicator of trust and performance.

The Future of Pipe Manufacturing

The pipe manufacturing industry is moving toward smarter and more sustainable solutions. Companies are now focusing on eco-friendly materials, energy-efficient production, and longer-lasting pipe designs. As water conservation and infrastructure development become more important, modern pipes will play a key role in shaping the future.

Conclusion

A dependable Pipe Manufacturing Company is essential for building safe, efficient, and long-lasting water and plumbing systems. By choosing products from a trusted PVC pipe manufacturer or CPVC pipe manufacturer, you ensure better performance, lower maintenance, and improved water safety. High-quality Water supply pipes are not just components of a building they are the lifeline of modern infrastructure.

Investing in the right pipes today means fewer problems and smoother water flow tomorrow.

FAQ:-

1. What does a pipe manufacturing company do?

A pipe manufacturing company designs, produces, and tests pipes used for water supply, drainage, and plumbing systems.

2. Why are PVC pipes so popular?

PVC pipes are lightweight, corrosion-resistant, affordable, and easy to install, making them ideal for drainage and cold-water supply.

3. What makes CPVC pipes different from PVC?

CPVC pipes can handle higher temperatures, making them suitable for hot and cold water plumbing.

4. Are water supply pipes safe for drinking water?

Yes, when manufactured by a certified pipe manufacturing company, water supply pipes are hygienic and safe for potable water.

5. How long do PVC and CPVC pipes last?

High-quality PVC and CPVC pipes can last more than 50 years when properly installed and maintained.

For any queries, contact the plumbing experts at Ajay pipes on the Toll Free No. : 1800-11-4050 or via email at our email address info@ajaypipes.com